Environment & Energy

Related: About this forumPanasonic Installs an In-house Hydrogen-based Renewable Energy Power Generation System in Its UK Factory

Panasonic Installs an In-house Hydrogen-based Renewable Energy Power Generation System in Its UK Factory

Using heat generated during pure hydrogen fuel cell generation to preheat water for the heating operation of the air conditioning system

Panasoniic.com | Press Release | Dec 03, 2024

image: Panasonic GREEN IMPACT logo

Tokyo, Japan – Panasonic today announced that it has completed the installation and begun trial operation of a demonstration power generation system at Panasonic Manufacturing UK Ltd. (Location: Cardiff, Wales, UK; hereinafter referred to as "PMUK" ), which develops, manufactures, and sells microwave ovens and other products. The microwave oven assembly factory is powered by renewable energy generated by the system through the integrated control of three types of energy sources: pure hydrogen fuel cell generators, photovoltaic generators, and storage batteries. PMUK will enhance resilience by efficiently generating and storing only the amount of electricity required on-site. Additionally, it will establish an energy management system (EMS) that tracks changes in the factory's electricity demand and weather changes in the UK. The EMS will begin operation by the end of March 2025 and provide a stable supply of renewable energy to the microwave oven assembly factory.

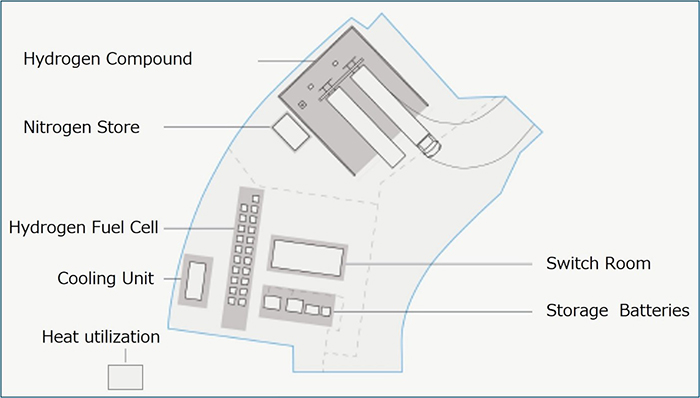

PMUK has installed 21 units of 5 kW pure hydrogen fuel cell generators as part of a distributed system optimized for the amount of electricity used in its microwave oven assembly factory. In combination with 372 kW photovoltaic generators and 1 MWh storage batteries, PMUK aims to operate the system to supply the necessary electricity from 100% renewable energy. The integrated control of 21 pure hydrogen fuel cell generators will level out the operating hours of each unit and improve maintainability, allowing for uninterrupted maintenance. Further, by using green hydrogen produced in the UK, the electricity used in the microwave oven assembly factory will be decarbonized. To power the microwave oven assembly factory, the photovoltaic power generation system for the demonstration uses an output of 372 kW, a portion of the total 760 kW output from photovoltaic power generators installed on the roof of the PMUK building last year. Panasonic will develop a highly effective solution that enables the integrated control of three types of batteries by combining existing photovoltaic generators with newly installed pure hydrogen fuel cell generators and storage batteries. The effectiveness of the solution will also be verified.

At this demonstration facility, heat generated during the electricity production by the pure hydrogen fuel cell generators will be used to provide heating and hot water in the microwave oven assembly factory, aiming to achieve an energy efficiency of 95% for the pure hydrogen fuel cell generators with the cogeneration effect. The heat generated during power generation will be used to preheat water for the newly installed "water circulation air conditioning system" (which collects heat from the atmosphere to create cold and hot water that is circulated around the room to adjust the room temperature), thereby further reducing power consumption during hot water heating operation through integrated heat utilization. Additionally, the factory aims to integrate the use of heat from existing electric boilers to reduce the power consumption required to supply hot water within the factory. When controlling the EMS, demonstration data will be accumulated concerning the balance of power supply and demand, dependent on changes in weather conditions, fluctuations in power demand, and other factors, while incorporating external local weather forecast data. This will help Panasonic accumulate know-how for enhancing the EMS, one of its core technologies, strengthen its supply and demand adjustment technology to minimize losses in the generation, storage, and transmission of renewable energy, and ensure a stable energy supply.

This demonstration uses green hydrogen for in-house power generation and integrates and controls three types of energy sources to run the factory on 100% renewable energy in environmentally advanced European countries. This globally unique initiative is the first attempt even for Panasonic. Through this demonstration, Panasonic aims to achieve a solution that is optimal for the characteristics of the region. Furthermore, through the operation of the demonstration system, the company will also seek to build relationships with local partner companies and business customers related to the hydrogen business to establish a business foundation. Aiming for a society where well-being and sustainability are compatible, Panasonic will create new businesses that contribute to UK society and climate change measures. It will also tackle efforts to develop its business from a long-term perspective toward the realization of a future hydrogen society and carbon neutrality...more

https://news.panasonic.com/global/press/en241203-4

Someone will probably call Panasonic Engineers "Ignorant"

efhmc

(15,046 posts)isitreal

(45 posts)Big oil does not like green hydrogen...it does not use fossil fuel when it is made.

NNadir

(34,847 posts)...is nothing more than greenwashing fossil fuels. It's a very, very, very, very successful scam. The laws of thermodynamics, which the advertisers here and elsewhere are happy people don't know, means that making hydrogen from fossil fuels destroys exergy and thus requires the use of more fossil fuels than the hydrogen can provide. It's an energy loser.

A Giant Climate Lie: When they're selling hydrogen, what they're really selling is fossil fuels.

Exxon, for instance, pushes hydrogen bullshit, not because they're green, but because they want to greenwash their industry, fossil fuels:

isitreal

(45 posts)yes I agree that the current production of h2 is from fossil fuels. I believe that is because the fossil fuel industry is desperate to find new ways to see their product. They also have lots of money available to develop the production. The thing is companies are just starting to produce true green h2. Looking at the benefit of using H2 it is so much better a method of storing energy. The weight of the current batteries and the recharge time makes H2 a much better fuel. Thinking that batteries are going to be the the fuel source for heavy trucks, long distance trucks and trains is a failure in my mind.

Here is some recent mile stones and comparisons of what the batteries weigh and the weight of H2 fuel used in a long distance truck demonstration. Also to refill the H2 tank is very fast, minutes verses hours.

https://www.yahoo.com/autos/futuristic-truck-breaks-world-record-103000780.html

The 33,000-pound H2Rescue was powered by a 250-kilowatt traction motor that consumed 168 kilograms of the 175 kilograms of hydrogen brought on board.

The weight of a Tesla Model 3 battery depends on the model and version of the car:

Long Range

The Long Range version of the Model 3 has a battery that weighs 1,060 pounds (480 kg). It has 4,416 cells arranged in 96 groups of 46.

Standard Range

The Standard Range version of the Model 3 has 2,976 cells arranged in 96 groups of 31.

Model 3 NCA battery - Short modules? | DIY Electric Car Forums

The battery pack in a Tesla Model 3 is made up of four rectangular modules that are bolted to the ground and encased in hard plastic. The two outer modules are 67.5 in (1715 mm) long and weigh 191 lbs (86.6 kg) each, while the two inner modules are 73 in (1854 mm) long and weigh 207 lbs (98.9 kg) each.

Electric car batteries are heavier than traditional car batteries because they need to store more energy. The average weight of an electric car battery is around 1,000 lbs, but can vary depending on the vehicle.

The battery for the Ford F-150 Lightning weighs 1,800 pounds (820 kg). This is a significant portion of the truck's weight, accounting for most of the extra weight compared to the gas-powered F-150. The Lightning's weight can range from 6,015 to 6,893 pounds (2,728 to 3,127 kg), depending on the model and trim

NNadir

(34,847 posts)The laws of thermodynamics make it obscene to run these scams.

The reactionary impulse to tear this shit out of wilderness is well, reactionary, because dependency on the weather - this at a time we have destabilized the weather with rank stupidity - for energy was abandoned in the late 19th and early 20th century for a reason.

isitreal

(45 posts)yes I agree that the current production of h2 is from fossil fuels. I believe that is because the fossil fuel industry is desperate to find new ways to see their product. They also have lots of money available to develop the production. The thing is companies are just starting to produce true green h2. Looking at the benefit of using H2 it is so much better a method of storing energy. The weight of the current batteries and the recharge time makes H2 a much better fuel. Thinking that batteries are going to be the the fuel source for heavy trucks, long distance trucks and trains is a failure in my mind.

Here is some recent mile stones and comparisons of what the batteries weigh and the weight of H2 fuel used in a long distance truck demonstration. Also to refill the H2 tank is very fast, minutes verses hours.

https://www.yahoo.com/autos/futuristic-truck-breaks-world-record-103000780.html

The 33,000-pound H2Rescue was powered by a 250-kilowatt traction motor that consumed 168 kilograms of the 175 kilograms of hydrogen brought on board.

The weight of a Tesla Model 3 battery depends on the model and version of the car:

Long Range

The Long Range version of the Model 3 has a battery that weighs 1,060 pounds (480 kg). It has 4,416 cells arranged in 96 groups of 46.

Standard Range

The Standard Range version of the Model 3 has 2,976 cells arranged in 96 groups of 31.

Model 3 NCA battery - Short modules? | DIY Electric Car Forums

The battery pack in a Tesla Model 3 is made up of four rectangular modules that are bolted to the ground and encased in hard plastic. The two outer modules are 67.5 in (1715 mm) long and weigh 191 lbs (86.6 kg) each, while the two inner modules are 73 in (1854 mm) long and weigh 207 lbs (98.9 kg) each.

Electric car batteries are heavier than traditional car batteries because they need to store more energy. The average weight of an electric car battery is around 1,000 lbs, but can vary depending on the vehicle.

The battery for the Ford F-150 Lightning weighs 1,800 pounds (820 kg). This is a significant portion of the truck's weight, accounting for most of the extra weight compared to the gas-powered F-150. The Lightning's weight can range from 6,015 to 6,893 pounds (2,728 to 3,127 kg), depending on the model and trim

ancianita

(38,881 posts)Thanks for this great news. ![]()

https://en.wikipedia.org/wiki/Panasonic

Artificial intelligence

Automation

Construction

Electrical equipments

Electronics

Entertainment

Fans

Home appliances

Industrial equipments

IoT

Lighting

Personal computers

Real estate

Rechargeable batteries

Robotics

Software

Revenue Increase ¥7.388 trillion (2022)[* 1]

Operating income Increase ¥357.5 billion (2022)[* 1]

Net income Increase ¥255.3 billion (2022)[* 1]

Total assets Increase ¥8.023 trillion (2022)[* 1]

Total equity Increase ¥3.347 trillion (2022)[* 1]